In 2015 the American Institute of Aeronautics and Astronautics (AIAA) Foundation held a Graduate Team Aircraft Design Competition open to undergraduate AIAA branches or at-large Student Members. They competed for prizes ranging from $500 for first place to $125 for third. The task was to design from the ground up a purpose-built large air tanker. Specifications for the aircraft included a crew of two pilots, 5,000 gallon retardant capacity, 2,500 nm ferry range, dash speed of 300 knots, and powered by turbofan or turboprop engines. Other criteria was a drop speed below 150 kt, stall speed of 90 kt, and takeoff from a Balanced Field Length of 5,000 ft. with an assumption of +35°F standard atmosphere at an altitude of 5,000 ft. above mean sea-level. In addition, fatigue stresses should be strongly considered.

In October, 2016 the AIAA announced the three winners. Today we are writing about the third place contestant — in subsequent days we will cover the second and first place winners. Yes, even though we covered the initial announcement of the competition, we are a little late to the party to write about how it turned out. (No sense in rushing into these things.)

Receiving the award for third place was a 10-person group from California State Polytechnic University, Pomona, who called themselves the AeroTactic Company Team. You can download their very, very technical 65-page proposal.

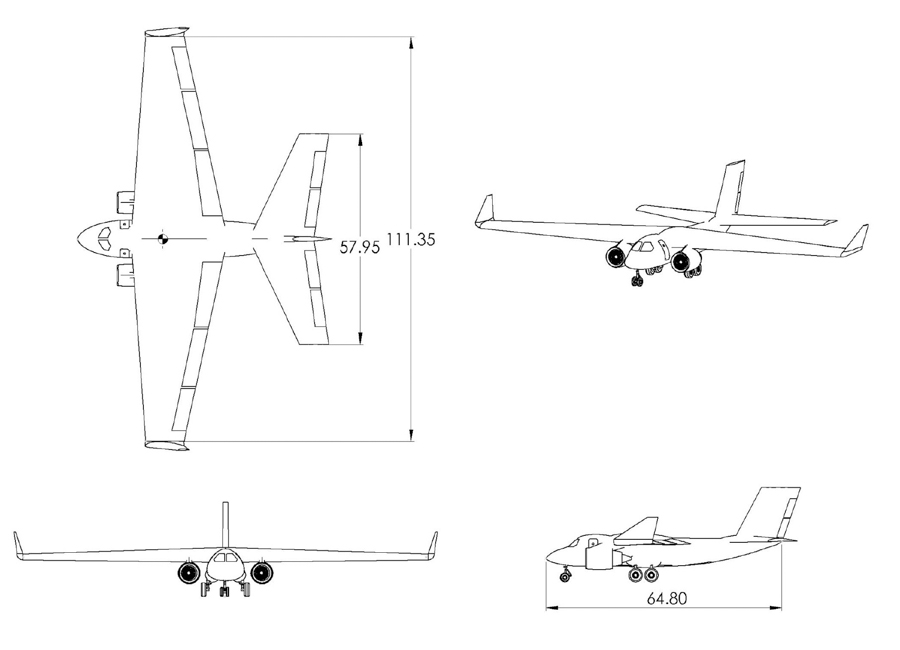

The team’s FF-1 Rainbird aircraft design features an integrated retardant tank with a gravity-fed dispersal system. It is powered by two Rolls Royce Tay turbofan engines underneath the wings. Winglets increased the Rainbird’s lift to drag ratio by 5%, consequently increasing its fuel efficiency.

Their rational for choosing to have it piloted rather than unmanned, was, “A piloted aircraft is more flexible to changing scenarios compared to a UAV. In addition, an unpiloted aircraft would cost more to maintain and to build due to the additional sensors, hardware, and software required.”

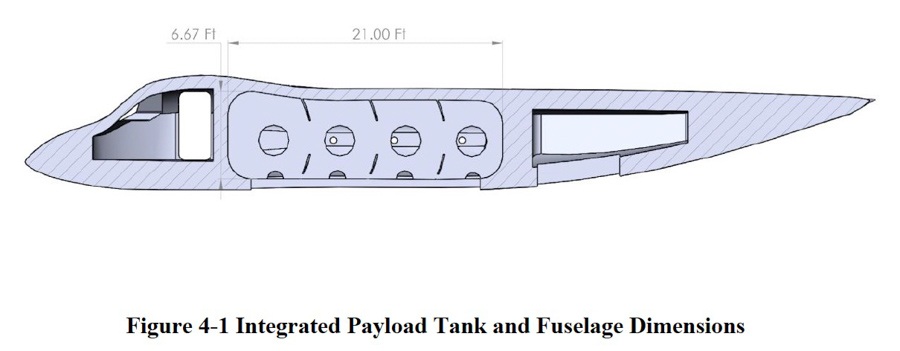

The high density payload combined with the low stall speed requirement drove the design of the aircraft to contain large wings and a small fuselage.

The two engines are attached to the wing’s leading edge, protruding past the wing in order to balance the aircraft for all loading configurations. It is capable of carrying enough fuel for four sorties and can reload the retardant within ten minutes.

The 5,000-gallon tank is located at the center of gravity of the aircraft, limiting CG shift while releasing its load. Their goal was for the fuselage to be as small as possible while still being long enough to maintain aircraft stability, hence the larger length of the tank relative to its other dimensions. The tank can be refilled from three fill ports simultaneously.

The group determined that for the aircraft to reach a fire 200 nm away in the least amount of time, 54 minutes, it should cruise at 20,000 feet at 245 kt.

The cockpit, but not the entire aircraft, would be pressurized and air conditioned. (Not all three of the student entries have pressurization.)

The aircraft will have two infrared cameras, priced at $4,200 each.

Cost

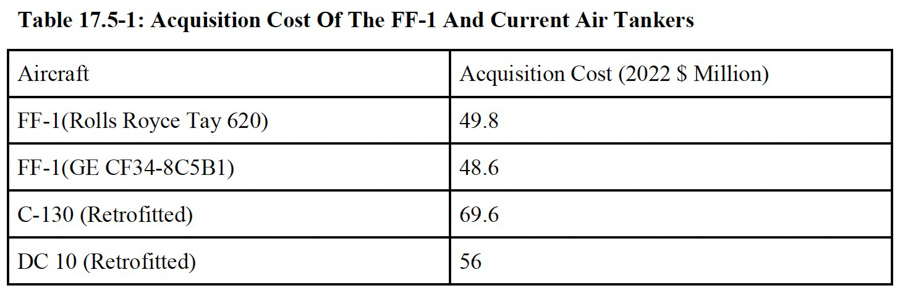

The graduate students assumed 200 units would be produced over the next 80 years with combined 20-year life spans covering 100 years. They estimated the research and development would cost $1.89 billion, including building and testing three aircraft. Total cost of production would be $89 billion, inflated to 2022 dollars (when delivery would begin). The flyaway cost for each unit was estimated at $45.3 million in 2022 dollars, including 10% profit. At 131 units, the program would break even in costs and begin to generate profit.

Below is an excerpt from the proposal:

“The cost comparison between the [students’] FF-1 and the C-130 and DC 10 was obtained through the analysis of depreciation, the costs associated with retrofitting an existing aircraft into an air tanker, and the limited life of the aircraft in the year 2022. The cost of retrofitting an air tanker was approximated to be $23.71 million, not to mention the installation of a retardant delivery system which is another $6.38 million. The cost for the both the C-130 and DC-10 were obtained from Military Aircraft. Table 17.5-1 exhibits the costs of the FF-1 configurations and the retrofitted competing aircraft.”

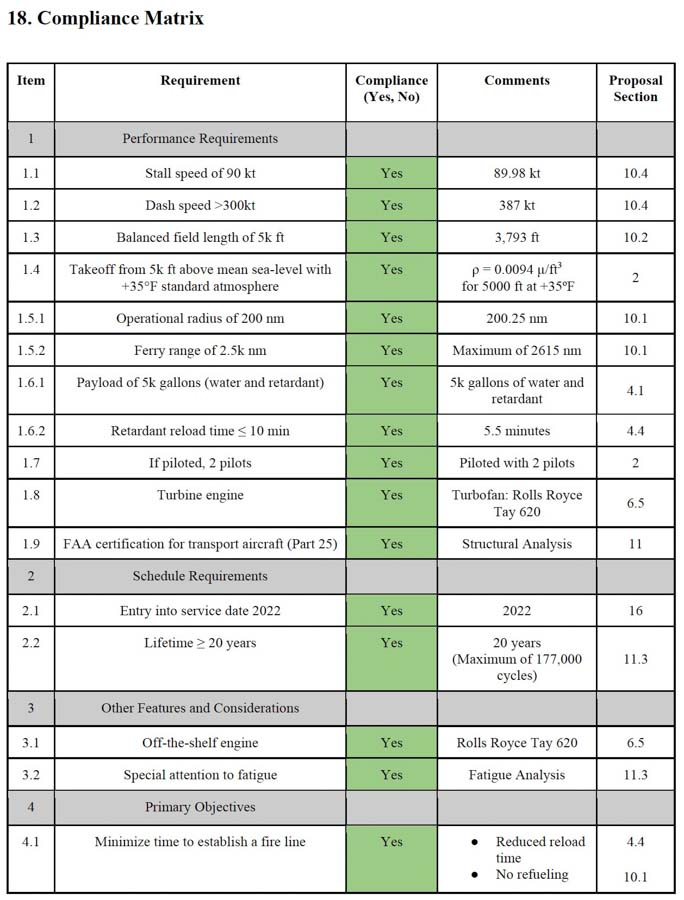

The table below shows how the design met the required specifications.

Too bad AIAA used FAR part 25 in the design criterion. They could have done better than using a “transport” category design FAR for a point design aircraft.