In 2015 the American Institute of Aeronautics and Astronautics (AIAA) Foundation held a Graduate Team Aircraft Design Competition open to undergraduate AIAA branches or at-large Student Members. They competed for prizes ranging from $500 for first place to $125 for third.

In October, 2016 the AIAA announced the three winners. The team that finished second represented Sharif University in Tehran, Iran, for their Anahita aircraft. On March 26 we wrote about the third place winning team. In a later article we will cover the team that took first place, but here we will describe the Sharif University entry in the competition.

The task from the AIAA was to design from the ground up a purpose-built large air tanker. Specifications for the aircraft included a crew of two pilots, 5,000 gallon retardant capacity, 2,500 nm ferry range, dash speed of 300 knots, and powered by turbofan or turboprop engines. Other criteria was a drop speed below 150 kt, stall speed of 90 kt, and takeoff from a Balanced Field Length of 5,000 ft. with an assumption of +35°F standard atmosphere at an altitude of 5,000 ft. above mean sea-level. In addition, fatigue stresses should be strongly considered.

Not being fluent in Persian, I looked up “Anahita”, the name the team gave their project, and found that it refers to an Iranian goddess associated with fertility, healing and wisdom.

Curiously, there was a fairly lengthy section in the team’s proposal discussing the feasibility of converting a 737 into an air tanker. The proposal was written in 2016, and in May, 2017 Coulson announced that they had purchased six 737-300s to convert them into 4,000-gallon “Fireliner” air tankers. Britt Coulson said they saw an opportunity when Southwest Airlines made a decision to replace their 737-300’s with the new 737-Max.

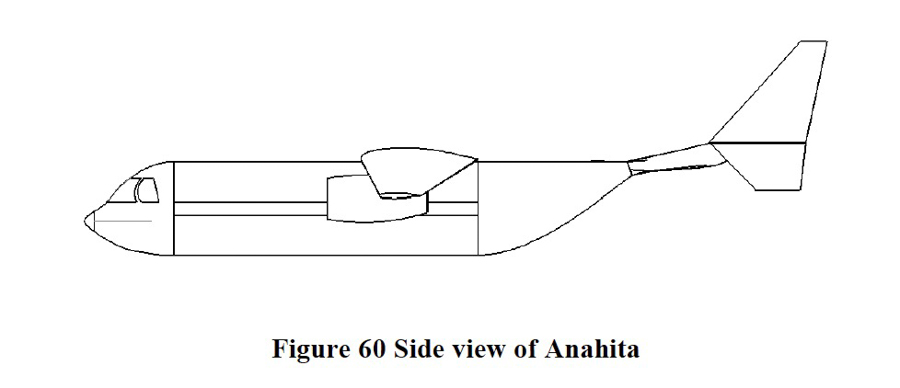

The students designed an aircraft with a high wing, “H” tail, and two turbofan engines under the wings. It would carry enough fuel for two sorties of three drops each.

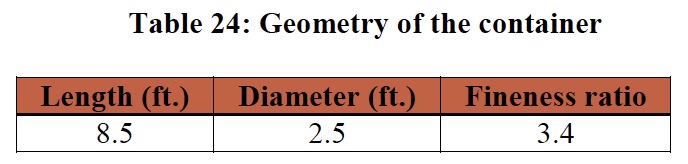

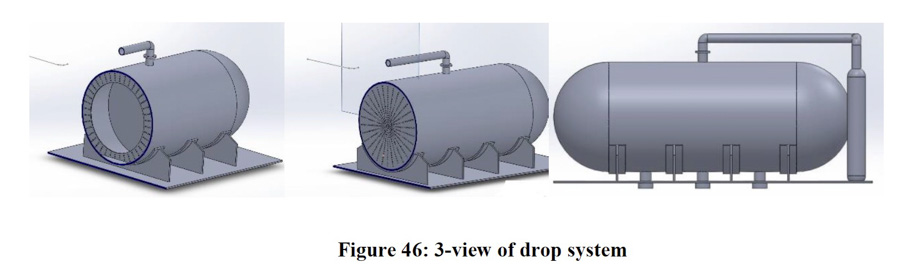

The retardant tank would be cylindrical, 8.5 feet long with a diameter of 2.5 feet. My calculations determined it would only hold 312 gallons, far short of the 5,000 gallon requirement.

The students specified that the tank would be pressurized, “…so the drop operation will be more precise and there will be no splashing.” But there was no description of how that would be accomplished — with an onboard air compressor, a ground-based compressor, or another method.

The proposal mentioned that the aircraft could also carry cargo, and in another section, that the tank could be removed in minutes. There were no other details about cargo; presumably the tank would be removed to make it multi-role capable. The document described the cargo door in a 737 but there was no mention of one in their purpose-built air tanker design.

The aircraft will have two pilots, and since it must be able to drop on its own without the need for a lead plane, the designers determined that an observer would be on board to monitor the fire. Extra windows cannot be installed in the cockpit because it would greatly increase structural fatigue. So for the observer to have an effective view of the fire area, five cameras will be embedded in the skin providing imagery to a Virtual Reality (VR) helmet worn by the observer, similar to the helmet worn by F-35 pilots. Two cameras would be in the nose, one in the middle, and two in the rear.

In order to determine the location of the drop, two infrared cameras would map the fire and, the students wrote, “…with the help of the geological data of the terrain and wind speed and direction, the fire behavior can be predicted by a computer and the optimal location of drop can be realized.”

Cost

They found an air tanker study that recommended an optimal number of 28 federal large air tankers. Based on production of 28, the unit cost would be approximately $279M. If 120 units were manufactured for worldwide use, the cost per unit would drop to $126M.

From the Conclusion section of the proposal

“It was realized that the 160-day contracts do not result in economical solutions to the LCC of Anahita, therefore, additional capability of performing alternate missions was considered. The 160 contracts per year were predicted to reach 208 by 2100, this indicates that the firefighting operation hours will increase in the future. Increase in the fleet was recommended in order to lower the unit cost, this was justified based on the increasing number of fires and 37 international agreements on forest fires between US and other countries, it was then indicated money for every player is guaranteed by Export Credit Loan, so foreign contractors could also be involved.”

You can download a copy of their proposal.

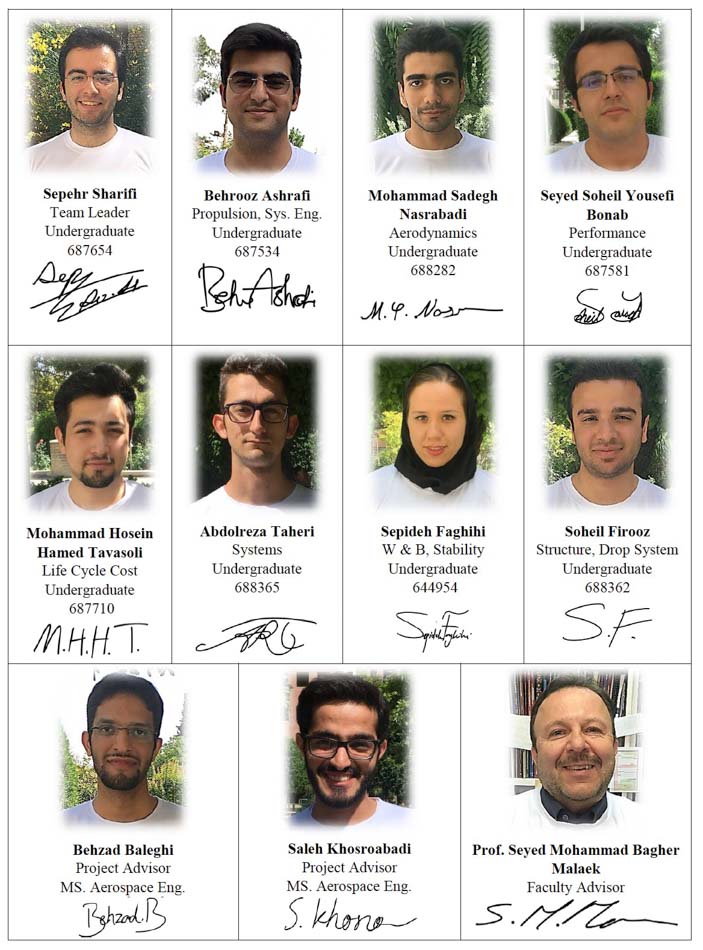

The designers:

Bill,

Change the tank dimensions from feet to meters and the volume is correct. Probably a misprint on their part.

No Vn diagram in their proposal like the 1st and 3rd place entries so no easy way to look at maneuverability and stall margin. From my limited aero, this doesn’t look like a very maneuverable design. Its just another modified transport class aircraft that as designed will will end up depending on the use of flaps to provide sufficient stall margin when maneuvering. Use of flaps will impose G limits that may prove to be less than satisfactory and result in occasional overstress during maneuvering and delivery phases.

Not totally sure how this one beat out the 3rd place entry considering some of the unmentioned details that you elaborated on.

That being said, putting enough cameras on the plane to enable the observer have a 360 degree view in VR is a real interesting idea. Something like that could possibly be adapted to existing tankers or (probably better) air attack platforms.

Not sure if it would be cost effective or technically feasible, but it is an interesting idea that I think merits additional consideration.