Results have been released for a three-year study on the use and effectiveness of water enhancing products for Single Engine Air Tankers (SEATs). It was conducted by Colorado’s Center of Excellence (CoE) for Advanced Technology Aerial Firefighting, and the Bureau of Land Management from 2017 through 2019. It is titled, “Aerial Firefighting Field Operational Evaluation of Water Enhancers; Results and Recommendations.”

In addition to long term fire retardant (LTR) which is usually used in large and very large air tankers, other water enhancing products are often used by SEATs and sometimes helicopters, and occasionally by large air tankers. For example the air tankers from North America that worked in Chile in recent years used products other than LTR. The enhancers are also used in Australia in addition to LTR. SEATs often use retardant but some bases have switched to other products.

Data was collected for the study through 95 evaluations of the performance of the water enhancers by aerial supervision personnel, pilots, ground firefighters, a mixer-loader, and by two dedicated field observers hired for that purpose during the final year of the project.

The CoE evaluated the following water enhancers:

- GelTech Solutions FireIce 561® (uncolored)

- FireIce HVO-F® (orange colorant)

- FireIce HVB-Fx®

- G5 BioSolutions BlazeTamer 380®

- Thermo Technologies Thermo-Gel 200®

(In the interest of full disclosure BlazeTamer is a supporter of Fire Aviation.)

The full 63-page report can be downloaded. Here are some of the recommendations:

Increase the Use of Water Enhancers (Especially During Initial Attack)

Aircraft are used in a variety of wildfire management roles in many parts of the world. They can be used to deliver suppressants to sections of the fire edge that are difficult to access on the ground and can reduce the intensity and spread rates to allow ground crews to work along the fire edge. This is critical during the initial attack of wildfires in remote locations.

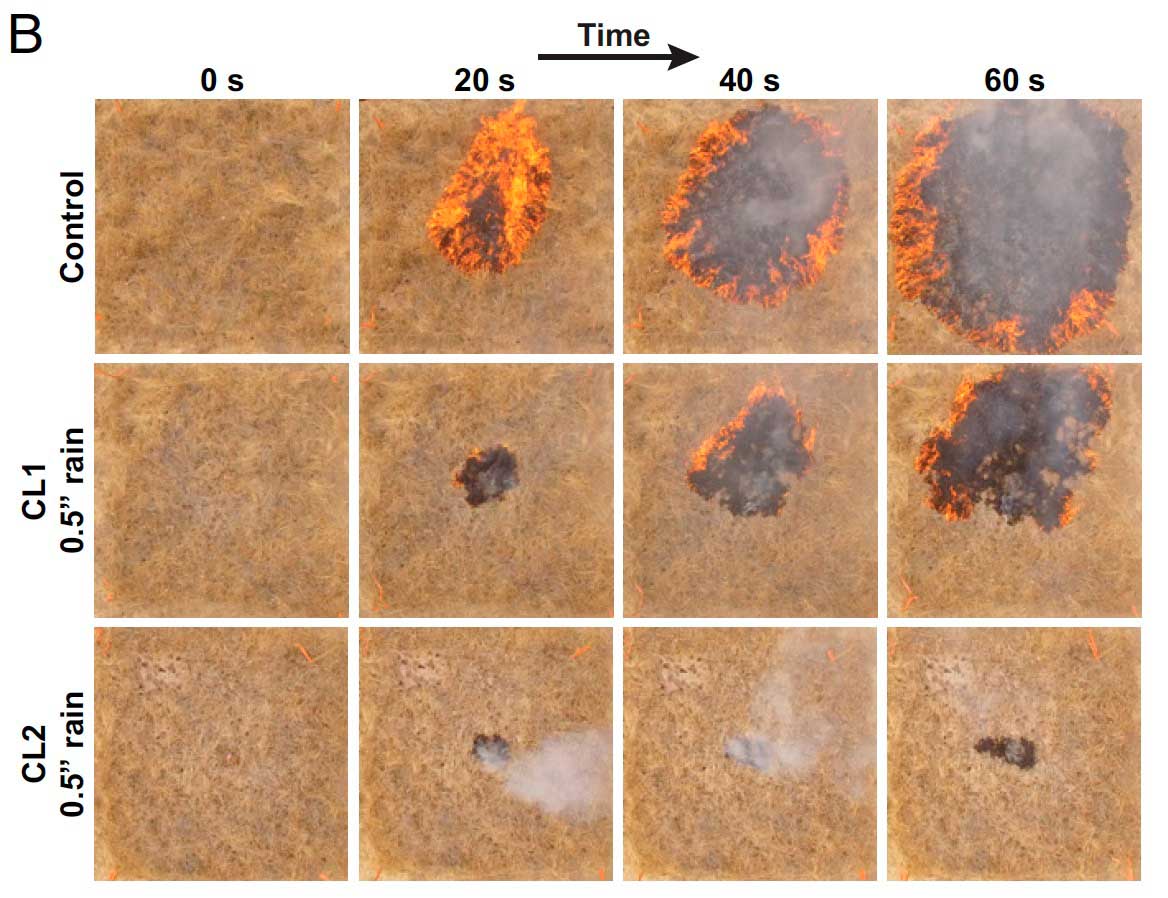

When used properly, specifically in direct attack on the fire with ground resources present, the CoE’s data showed that there is a favorable reduction in flame heights with the use of water enhancers as opposed to LTR, especially in light fuels. Observers shared a number of comments that suggest that they are quite effective at reducing fire behavior.

- Water enhancers are much more effective when used in direct attack than water or foam and much less expensive than retardant.

- The choice of tactics may also depend on the availability of suitable aircraft, payload, and airbase facilities for each option.

- Water and foam all dry at a faster rate than do water enhancers; however, ground follow-up is critical to the success of a water enhancer line “holding.” This is even more important on hot and windy days when spread rates and the probability of ignition are both high, as holding times under these conditions will be 30 minutes or less.

- Holding time was difficult to quantify because many of the drops were not observed at all or did not last long enough to capture data.

- The CoE’s study showed that holding times for the products that were evaluated range from 20 minutes to 2 hours. Because the water enhancers are only effective as long as they retain water, fire managers must realize that the use of these products should be limited to direct attack applications.

Consider Use of Water Enhancers in Helicopters

Use of water enhancers in helicopters should also be considered on large fires to directly support crews in controlling hot spots and reducing the amount of time required to control critical sections of fireline.

Some additional benefits of water enhancer use in helicopters may include:

- Fireline production per drop when using water enhancers is increased significantly due to the creation of a dense, narrow drop pattern versus the pattern created when dropping untreated water.

- Retardant is expensive and inefficient when used for direct attack. Retardant increases the weight of water from 8.3 lb per gallon to about 9.1 lb per gallon.

- Only 85% of retardant (i.e., the water content) is effective when used for direct attack; 15% is the chemicals and coloring agent used for indirect attack.

- Retardant is more expensive. For example, BlazeTamer 380 costs $0.83 per gallon as compared to $2.50 per gallon for Phos Chek 259-F LTR.

- Ease of set-up and breakdown of water enhancer mixing systems as compared to mobile retardant bases allows for fast movement around a fire rather than having to stay in one location. No heavy equipment is needed.

Use Water Enhancers with Prompt Ground Resource Follow-Up

When enhancers are used properly for direct attack and the number of aircraft is sufficient, they may be capable of fully extinguishing the fire with little to no ground support. The CoE recommends water enhancer use for situations where follow-up from the ground can be provided promptly (typically within 1 hour).

For an extended attack incident, particularly when the ground support is several hours away and the need is to hold or slow the spread until they can catch up, retardant is likely the best tool. There were numerous observations made during this study in which the enhancers were very effective when supported by ground resources. Ground crews play an essential role during fire suppression, with water enhancer technology offering a method to increase their suppression capacity. Aerial suppression provides a temporary holding role, rather than extinguishing fires. Follow-up by ground crews before the water enhancers dry out or fire burns through the drop zone is essential.

In 2018, the CoE received observations from several initial attack fires with high rates of spread and intensity where ground resources were delayed in supporting the drops in a timely manner, resulting in drops being burned around or spotted over.

There were other recommendations about training, using an aircraft with an electro-optical/infrared sensor to evaluate the effectiveness of the drop, and processes to ensure quality control of the water enhancer mixture.